Building Out an Operations Organization

As your company shifts from development to manufacturing and sales the demand for a new set of functional experts and tools can be a choke point due to the challenge of finding candidates with appropriate breadth of experience and transitioning them in the timeframe needed. My prior experiences in commercialization, financial management and operations made me a fit for Memjet as it made that transition, and I can serve in that capacity for you. This can be either as an interim operations lead or as a mentor to your designated lead, working with them on priorities and planning for the operations function.

Areas of Expertise:

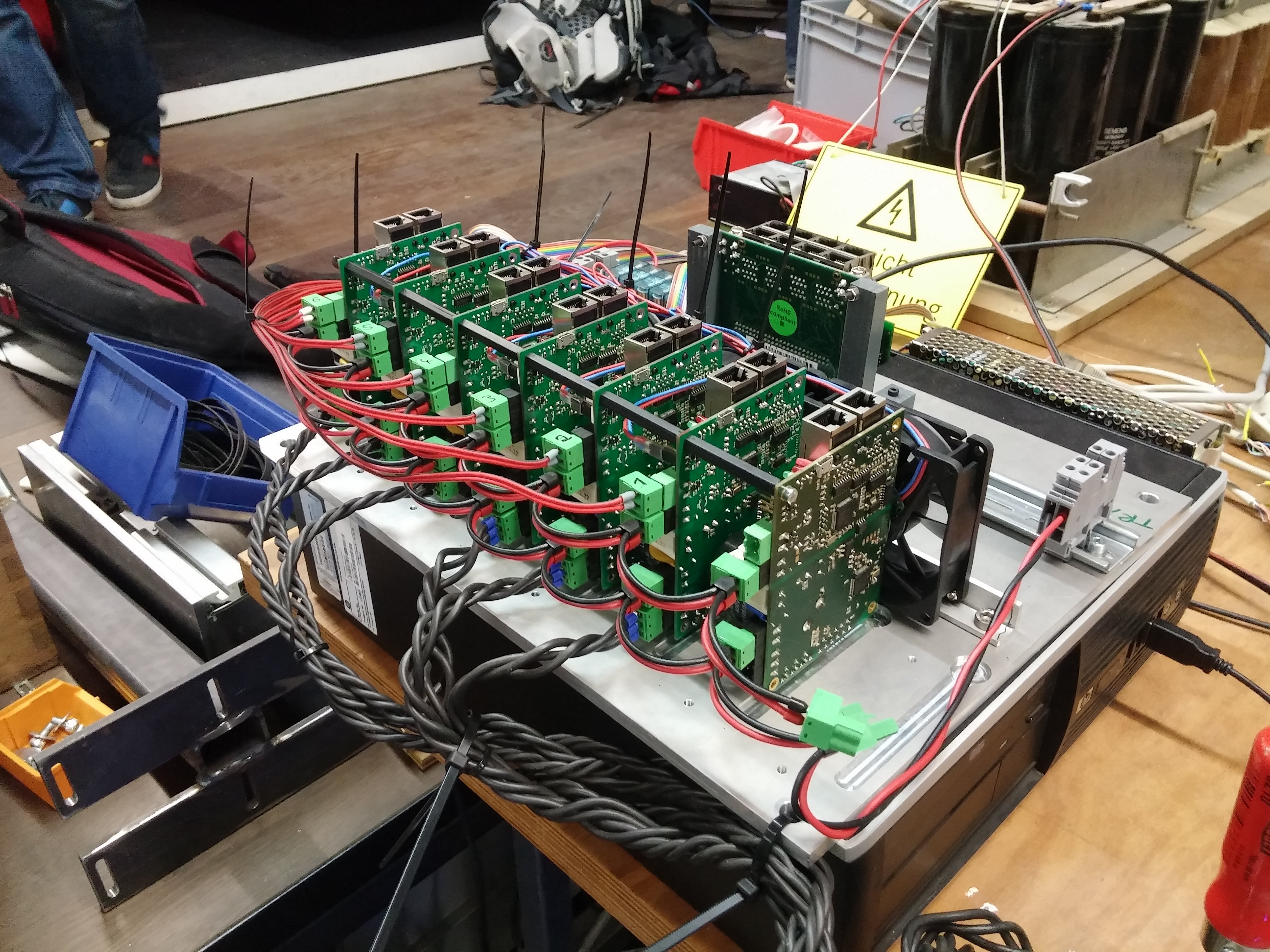

Demand and Supply Planning

Sales and Operations Planning

Product Lifecycle Management system setup

Order Management (entry and fulfillment)

Customer Support and Service

Spare Parts planning

Current Engineering and Quality

Purchasing, Manufacturing leadership